brinell hardness test lab report pdf|brinell hardness testing charts : manufacture PDF | This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test | Find, read and cite all the research you need on ResearchGate

Windguru weather forecast for Argentina - Viale (Casa). Special wind and weather forecast for windsurfing, kitesurfing and other wind related sports.

{plog:ftitle_list}

WEB14. País de produção. Reino Unido, Estados Unidos. Minha Vida com a Família Walter. (2023) Título Original: My Life with the Walter Boys. 1 Temporadas. Temporada 1. .

As part of the first lab, Brinell Hardness test will be used to determine the level of hardness applied from a 10 mm steel ball indenter onto a steel and aluminum . Brinell hardness number (BHN) is obtained by the ratio of the calculated load and the spherical area of the Indentation or Impression made on the specimen by the .

Practical application of engineering skills, combining theory and experience, and use of other relevant knowledge and skills. Analyze a problem, identify, formulate and use the appropriate .brinell hardness test The Brinell test for this experiment uses steel ball with different diameters which is pressed into a specimen by a different load that is maintained for 15 to 30 seconds.The Brinell hardness test method consists of indenting the test material with a 10 mm diameter hardened steel or carbide ball subjected to a load of 3000 kg. For softer materials the load can .

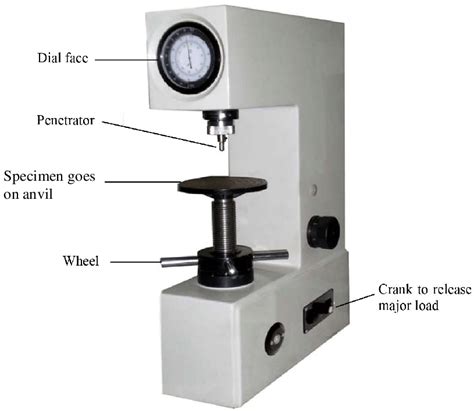

PDF | This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test | Find, read and cite all the research you need on ResearchGateused to perform the Brinell hardness test. 3.1.7 Brinell hardness testing machine—a Brinell hardness machine used for general testing purposes. 3.1.8 Brinell hardness standardizing machine—a Brinell hardness machine used for the standardization of Brinell hardness test blocks. The standardizing machine differs from atensile tests. The most popular methods are Brinell, Vickers and Rockwell hardness tests for metals and alloys. Brinell Test In a standard Brinell test 10 mm diameter hardened steel ball is forced to penetrate the material by 3000 kgf for steels and .Brinell Hardness Test Lab - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document describes a tension test experiment conducted on steel and aluminum samples. Key steps included measuring sample dimensions, installing samples in a tension testing machine, recording load and deformation readings during testing, and analyzing .

View Brinell_hardness_test_Lab_report.docx from MECH 244 at Concordia University. Brinell Hardness Test ENGR 244-KI-X Mohamed-Sofiane Ferrani 40132826 Partner: Sophie Koren February 6th, AI Chat with PDF The Brinell hardness test ing uses indenters made of st eel to test materials with hardness values of up to 350 HB, or of hard metal (tungsten) to test materials with har dness values from 350 to .

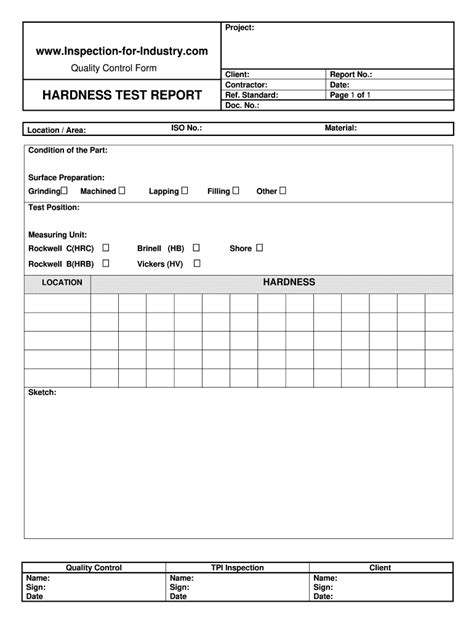

HARDNESS TEST (LAB REPORT) - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This lab report details an experiment measuring the hardness of four metals - aluminum, copper, brass and mild steel - using a Brinell hardness test. Students used a universal testing machine to apply a 10kN force for 10 seconds to .MATERIAL TESTING LABORATORY I - CYCLE 1. Izod Test 2. Brinell Hardness Test 3. Shear Test 4. Bending Test II – CYCLE 5. Charpy Test 6. Rockwell Hardness Test 7. Torsion Test 8. Compression Test III– CYCLE 9. Heat Treatment 10. Tensile Test IV – .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

Guidelines for students for report preparation 14. Lab assessment criteria 15. Details of Conducted Experiments 16. Lab Experiments . Strength of Material Lab (LC-ME 214G) . To study the Brinell hardness testing machine & perform the Brinell hardness test. 2. To study the Rockwell hardness testing machine & perform the Rockwell hardness test.Lab Report - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document describes procedures for three hardness tests - the Brinell hardness test, Rockwell hardness test, and Vickers hardness test. It explains the theory behind hardness testing and how each test works, including applying loads, measuring indentations, and calculating .

Report on Hardness test - Download as a PDF or view online for free. Submit Search. . The Brinell hardness test method consists of indenting the test material with a 10 mm diameter hardened steel or carbide ball subjected to a load of 3000 kg. For softer materials the load can be reduced to 1500 kg or 500 kg to avoid excessive indentation.The Brinell hardness test consists in indenting the metal surface with a 10-mm diameter steel or tungsten carbide ball at a load . Although not as reliable as the Brinell and Vickers hardness tests for laboratory purposes, the Rockwell test is widely used in industry as it is quick, simple and direct reading. UniversalFigure 1 - Schematic Diagram of Brinell Hardness Test h1 h2 P minor = 10 kg P major = 60, 100 or 150 kg Brale (diamond cone) or ball indentor Brale (diamond cone) . Include the following information in the laboratory report. 6061-T6 aluminum 1018 (HR) or A36 steel BHN (kg/mm2)...[measured] BHN (kg/mm2). [literature]

rockwell hardness tester procedure pdf

Brinell Hardness Test Schematic . Hardness is determined by taking the mean diameter of the indentation and calculating . the Brinell hardness number (BHM or HB) by dividing the applied load by the surface area of . Attach the table as an appendix to your lab report!) 2. Using the above converted values, calculate the UTS and YS values using .lab report 03 materials engineering experiment no. 02 rockwell hardness test of given sample introduction: hardness of material is generally defined as. Skip to document. . The hardness test is a mechanical test for material properties .

node js 100 connection test package

METHOD FOR BRINELL HARDNESS TEST FOR METALLIC MATERIALS ( Third Revision) 1 Scope This part of ISO 6506 specifies the method for the Brinell hardness test for metallic materials and is applicable up to the limit of 650 HBW. For specific materials and/or products, particular International Standards exist (i.e. ISO 4498-l). 2 Normative referencesApplications for Brinell Methods Brinell testing is suitable for measuring the hardness of rela-tively soft materials, including low-carbon steels, aluminum, lead, copper, and some plastics. The use of a large indenter and high load helps to minimize the effect of surface irregu-larities and yields more accurate hardness values. Soft Materials .

The document describes a Brinell hardness test experiment performed on steel, brass, and aluminum specimens. Various loads between 500-2500 kg were applied using a 10 mm tungsten carbide ball indenter. The indentation diameters were measured with a vernier caliper and converted to curved surface areas. The Brinell hardness numbers were calculated using .Lab Report 1 Brinell Hardness Test. Philip Leiriao 40126079 ENGR 244 Summer 2020 Concordia University Montreal, QC, Canada. Objective The objective of this experiment is to use the Brinell Hardness test to evaluate and calculate the .Metallic materials — Brinell hardness test — Part 1: Test method 1 Scope This part of ISO 6506 specifies the method for the Brinell hardness test for metallic materials. It is applicable to both fixed location and portable hardness testing machines. For some specific materials and/or products, particular International Standards exist (e.g .Download Brinell Hardness test and more Advanced Machining Processes Lab Reports in PDF only on Docsity! Experiment No. 1 Brinell Hardness Test Shiva Yadav (Dated: August 10, 2022) This report is a summary of the experiment to determine the Hardness of materials known as the ”Brinell Hardness Testing Method”.

ISO 6506-1:2005, Metallic materials — Brinell hardness test — Part 1: Test method ISO 6506-2:2005, Metallic materials — Brinell hardness test — Part 2: Verification and calibration of testing machines 3 Manufacture of reference blocks 3.1 The block shall be specially manufactured for use as a hardness-reference block.Rockwell Hardness Testing of Metallic Materials Lab Report - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document describes procedures for harness testing of metallic materials using the Rockwell scale. The Rockwell hardness test measures the indentation made by specific loads on a material's surface. There are different Rockwell scales .The mechanical properties of materials are ascertained by performing carefully designed laboratory experiments that replicate, as nearly as practical, the service conditions. . Rockwell hardness differs from Brinell hardness testing in that the indentation size is measured in Brinell testing while Rockwell hardness is determined by the depth .e2-Brinell Hardness Test - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. This document describes an experiment using the Brinell hardness test method. The objectives are to familiarize students with the Brinell test and expose them to another hardness testing method. The experiment involves indenting samples of stainless .

Brinell Hardness Testing The first widely accepted and standardized indentation-hardness test was proposed by J. A. Brinell in 1900. Brinell's interest in materials science grew during his involvement in a several Swedish iron companies and his desire to have a consistent and fast means of determining material hardness.

hardness tester lab report pdf

hardness test lab report pdf

webA plataforma mais completa do Mercado para Vendas no WhatsApp. Integrações com Correios, Jadlog, Melhor Envio, Frenet, Cielo, Mercado Pago, PagSeguro e PicPay.

brinell hardness test lab report pdf|brinell hardness testing charts